In 2014, Liangheng Xu, a distinguished artisan in China with almost two decades of experience, assumed the role of Chief Director at CHARLENE High Jewellery Workshop.

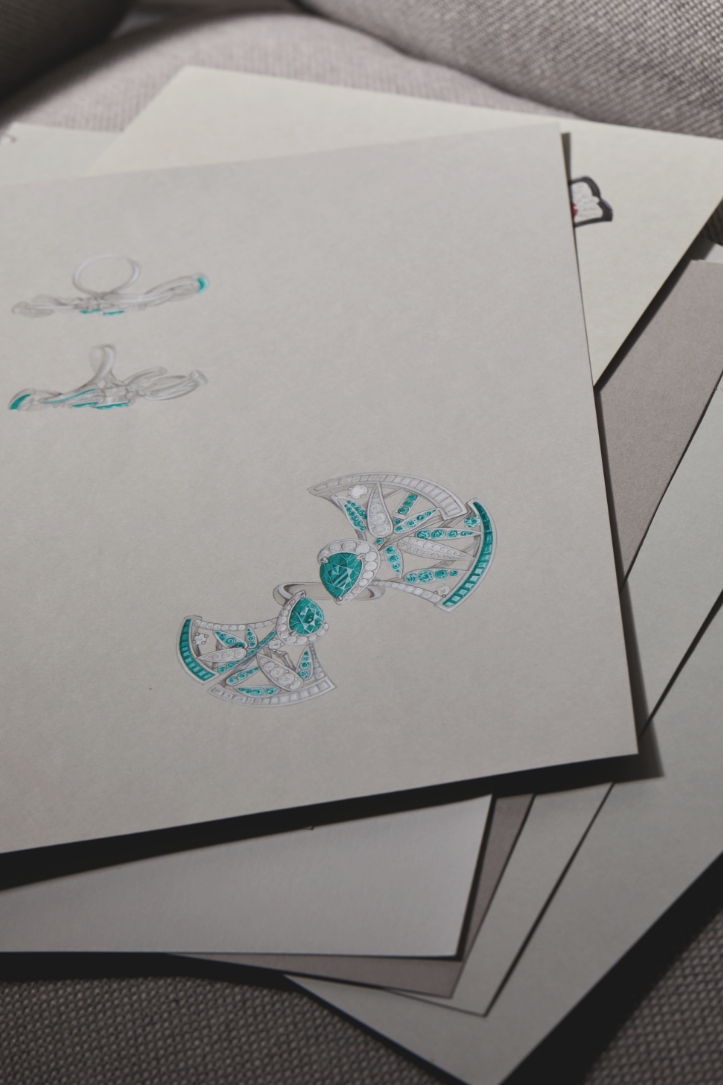

With Each Stroke, Each Incision

Artisans Shape Countless Pieces

of Jewellery that Bear the Weight of Time

CHARLENE's products are increasingly embraced by a growing number of users, earning recognition and appreciation.